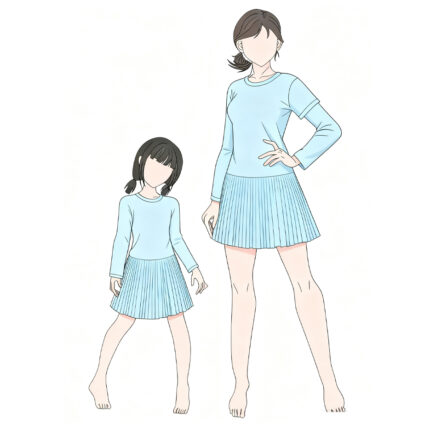

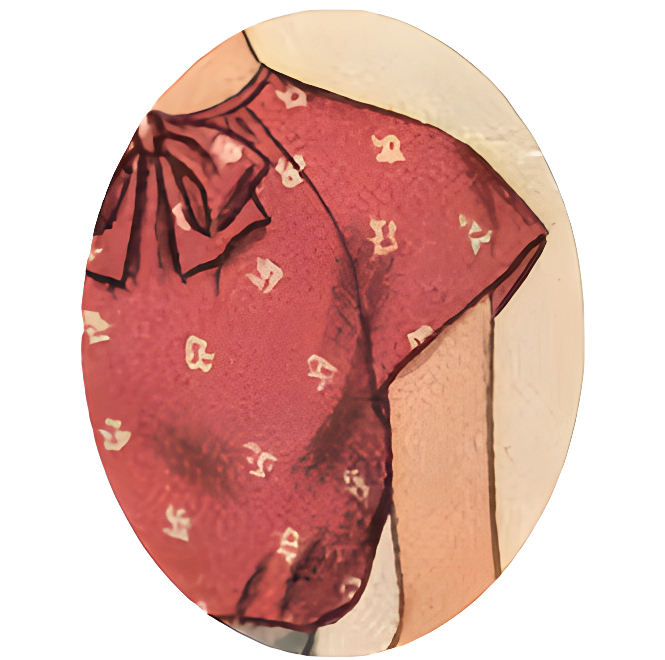

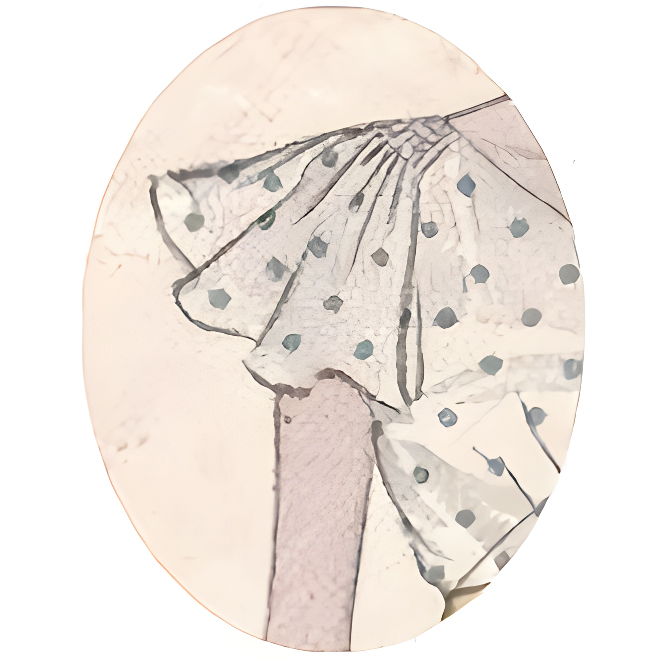

If you are looking for a kids’ dress that is cute, wearable, easy to sell, and highly customizable for your own brand, this striped pleated girls’ dress from Delpnana is a great choice. Designed for comfort and high retail conversion, perfect for boutiques, online stores, subscription boxes, and apparel wholesalers who want dependable quality and flexible OEM/ODM support.

🌟 Product Highlights

Soft, comfortable fabric suitable for sensitive skin

Classic round neckline with a youthful silhouette

Short sleeves and a clean fit for daily wear

Vibrant candy stripes that look lively and fun

Flowing pleated skirt with great movement and volume

Suitable for everyday wear, school outfits, family outings, and photography

🧵 Customization Options (OEM/ODM)

At Delpnana, customization is our core strength. Your business can adjust:

Colors & stripe patterns

Length, fabric weight, printing or embroidery

Size range from toddlers to bigger girls

Neckline, sleeve, and trim options

Brand labels, packaging, wash tags

Low MOQ starting from 2 pieces/sets

We work with many small-to-medium apparel brands in the US and AU that require flexible order support without sacrificing quality.

🏭 Why Work With Delpnana?

10+ years focused on custom children’s apparel

Bulk lead time: 4–6 weeks

Sample time: 15–25 days

Reliable production and strict quality control

Experience working with boutique brands, online retailers, and private label clients

High customer repeat rate thanks to stable quality

📌 Suitable Business Types

This item performs especially well for:

Kidswear brands

Online stores & Shopify boutiques

Subscription clothing boxes

Wholesale distributors

Personalized product sellers

Designers needing small-batch production

🌍 Market Compatibility

Designed to fit style and purchasing preferences in:

United States 🇺🇸

Australia 🇦🇺

Colors and silhouettes reflect current kidswear trends in these markets—simple, fun, and easy to match.

❓ FAQ

1) Are you a factory or trading company?

Yes, we are a real factory based in Foshan, Guangdong. We’ve been doing OEM/ODM for more than 14 years, with production, trading, and logistics in place.

2) Can I use my own labels?

Yes — labels, packaging, hangtags, care labels, anything.

3) Can I customize fabric, color, and sizing?

Of course. We can customize colors, prints, fabrics, sizes. If you have your tech pack, we’ll follow it.

4) What’s your MOQ? Can I test small quantity first?

Most fabrics also work with 2 pieces per size, so yes, you can test small orders first to see our quality.

5) How long do samples and bulk take?

Samples usually around 15 working days. Bulk around 4–6 weeks, depending on order size and complexity. Tell us your schedule and we’ll try to fit it.

6) How do I place an order, and what payment methods do you take?

Just share what you want to make, and we’ll discuss the details. Payments we support include PayPal, bank transfer, and Alibaba Pay.

7) What about shipping?

Sea, air, express, land — all are possible. Prices vary depending on courier and shipment size. Express like DHL or FedEx is usually cheaper for small packages.

8) Any discounts?

Yes — long-term clients get better pricing, and we usually offer seasonal discounts for sample orders around Christmas and Chinese New Year.

9) What products do you mainly make?

Lots — dresses, rompers, pjs, shorts, pants, tops, sets, family matching, swimwear, sweaters, dancewear, etc.

10) Are samples free?

No, but we don’t try to profit from them. Our pricing is fair — not the cheapest in the market, not the most expensive, but good value for genuine quality.

🟠 Why OEM Is a Smart Move for Clothing Brands

Focus on what actually grows the business

Outsourcing production saves factories, machines, hiring, training — so brands can spend more time designing, promoting, and selling.

Lower production cost, higher efficiency

OEM factories buy fabrics in bulk and have trained workers and production lines. Cost per piece is usually much lower, and this matters a lot in childrenswear, where margins need control.

Get access to professional techniques

Working with a factory means you don’t need to build printing, embroidery, heat-transfer equipment, etc. yourself. Factories like ours already handle screen printing, DTG, embroidery, water-based inks, etc., letting your product stand out.

🟡 How to Pick the Right OEM Factory

Define what you want

Before looking for factories, brands should clarify:

- Fabrics

- Printing or decoration type

- Design complexity

- Whether your brand is premium niche or mass market

Check experience & certifications

Factories with long history and certifications like ISO 9001 are generally more reliable and more standardized.

Check capacity & flexibility

A good OEM partner should be able to handle both small trial orders and large runs. Delpnana, for example, accepts both — good for long-term cooperation.

Quality control matters

Look for factories with:

- QC checklists

- Testing labs

- Third-party test reports if needed

Transparent pricing

Good quotes explain fabric, trims, labor, packaging, shipping, etc. Clear pricing + flexible payment terms helps manage cash flow better.

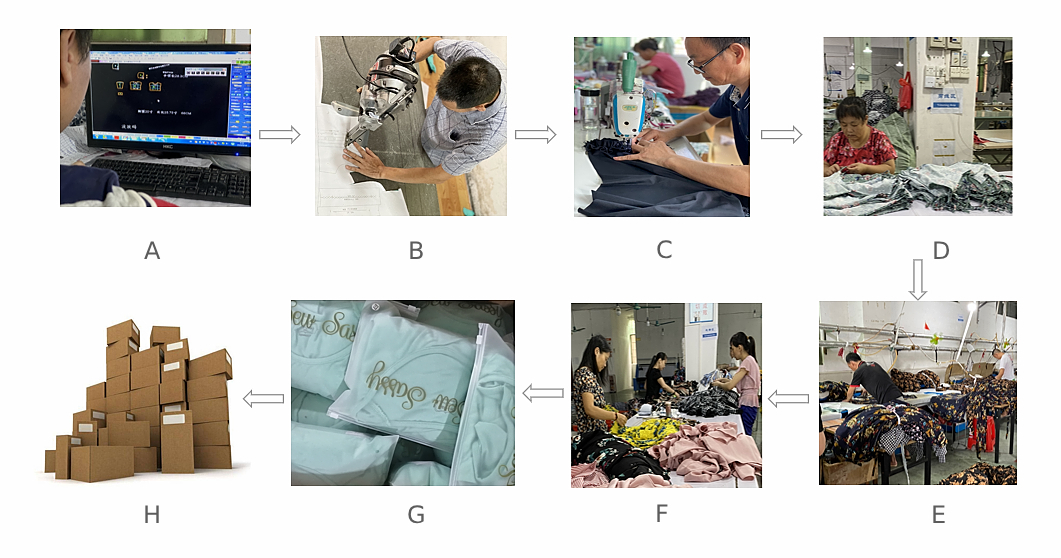

🟢 What OEM Production Flow Looks Like

Design & samples

You provide CAD/tech pack, Pantone colors, pattern files. The factory should help create samples in a reasonable time.

Material sourcing

Could be organic cotton, recycled fabrics, OEKO-TEX materials, etc. A capable factory will help source and check standards.

Bulk production

There should be scheduled updates — messages, photos, or dashboards — so buyers know progress. ERP systems help avoid delays.

Packing & delivery

Factories can offer branded packaging, hangtags, printed bags, eco pack, etc. Delivery could be express, DDP, sea, air, etc.

Project management

Tools like Trello, Asana, Monday.com can help track timeline, who’s responsible, and what needs to be delivered.

🔵 Risk Control & Partnership Protection

Contract with clear rules

Should list delivery dates, quality tolerance, penalties, and after-sales handling.

IP protection

Include NDAs, IP ownership, and trademark clauses — your designs stay yours.

Multiple suppliers

For important products, some brands keep two suppliers just in case something unexpected happens.

🟣 Where OEM Apparel Is Heading

Sustainable production

Consumers care more about the environment, so OEM is moving toward:

- Recycled fabrics

- Organic cotton

- Water-based printing

- Low-carbon logistics

Agile small-batch production

Faster delivery and data-driven production help brands launch trends quickly and avoid dead stock.

Customization

Personal embroidery, heat-transfer names, custom packaging, and small collections help brands build loyalty. Delpnana has over 10 years of experience doing custom maternity & kids clothing, and feedback has been consistently positive.

⚪ Final Words

Working with a strong OEM factory helps brands grow faster, keep costs under control, and maintain consistent quality. The right partner is not just a supplier but part of your long-term development — especially in a market where sustainability and customization are becoming the new normal.